Contact Us

Yantai Daoqin Wear Resistant Materials Co., Ltd.

Tel:0535-5657872

Fax:0535-3358698

Phone:13853547872,18953547698

Code:265607

E-mail:daoqin@plcastbasalt.cn

Add:Changsheng Business Plaza,Penglai City, Shandong Province, China

alumina ceramic lined steel pipe

Physical and Chemical Properties of Alumina Ceramic

|

Category |

Unit |

Technical Indicator |

||

|

alumina content |

wt% |

92 |

≥95 |

≥99 |

|

density |

g/cm2 |

3.6 |

3.7 |

3.8 |

|

hardness |

HRA≥ |

85 |

88 |

90 |

|

compressive strength |

MPa≥ |

1900 |

2500 |

2800 |

|

bending strength |

MPa≥ |

270 |

300 |

350 |

|

expansion coefficient |

×10-6/℃ |

8 |

7.5 |

7.5 |

|

elasticity modulus |

GPa |

300 |

300 |

300 |

|

heat conductivity coefficient |

W/m20℃ |

27 |

20 |

20 |

|

water absorption |

% |

≤0.02 |

≤0.02 |

≤0.02 |

|

abrasive resistance |

g/ cm2 |

0.2 |

0.1 |

0.1 |

|

acid resistance |

mg/ cm2 |

0.7 |

0.7 |

0.7 |

|

alkali resistance |

mg/ cm2 |

0.2 |

0.1 |

0.1 |

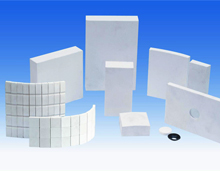

Alumina ceramic lined steel pipe is wear resistant composite materials which lining alumina pipe and alumina tile on the inner surface of the steel. It is the recombination of ceramic and steel and possesses all the good performance of two materials. Alumina ceramic lined steel pipe has excellent performance in wear resistance, corrosion resistance, high temperature resistance and impact resistance. Because of the smooth surface of the conveying material, the material can be transit fluently. Alumina ceramic lined steel pipe also has advantages of light-weight and easy to install feature.

Widely used in the following pipeline transportation: coal powder and ash of the power plant, mine concentrates and tailings, coal powder of coal mine, the scorched particle of coking plant, port pulp and sediment transport, wear-resistant materials of sintering plant, chemical and liquid aluminum and other corrosive media.

Alumina ceramic lined steel pipe is using high temperature plastic pasted the alumina ceramic tile to the inner wall of steel pipe. The advantage is good wear resistance, widely using range, without being limited by the substrate size and low cost.